Emulsion

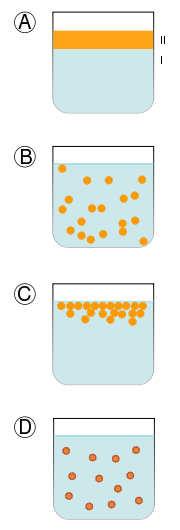

B. An emulsion of Phase II dispersed in Phase I.

C. The unstable emulsion progressively separates.

D. The surfactant (purple outline around particles) positions itself on the interfaces between Phase II and Phase I, stabilizing the emulsion

An emulsion (pronounced /ɨˈmʌlʃən/[1]) is a mixture of two or more immiscible (unblendable) liquids. Emulsions are part of a more general class of two-phase systems of matter called colloids. Although the terms colloid and emulsion are sometimes used interchangeably, emulsion tends to imply that both the dispersed and the continuous phase are liquid. In an emulsion, one liquid (the dispersed phase) is dispersed in the other (the continuous phase).

Examples of emulsions include vinaigrettes, the photo-sensitive side of photographic film, milk and cutting fluid for metal working.

Contents |

Appearance and properties

Emulsions are made up of a dispersed and a continuous phase; the boundary between these phases is called the interface. Emulsions tend to have a cloudy appearance, because the many phase interfaces scatter light that passes through the emulsion. Emulsions are unstable and thus do not form spontaneously. The basic color of emulsions is white. If the emulsion is dilute, the Tyndall effect will scatter the light and distort the color to blue; if it is concentrated, the color will be distorted towards yellow. This phenomenon is easily observable on comparing skimmed milk (with no or little fat) to cream (high concentration of milk fat). Microemulsions and nanoemulsions tend to appear clear due to the small size of the disperse phase.

Energy input through shaking, stirring, homogenizing, or spray processes are needed to initially form an emulsion. Over time, emulsions tend to revert to the stable state of the phases comprising the emulsion; an example of this is seen in the separation of the oil and vinegar components of Vinaigrette, an unstable emulsion that will quickly separate unless shaken continuously.

Whether an emulsion turns into a water-in-oil emulsion or an oil-in-water emulsion depends on the volume fraction of both phases and on the type of emulsifier. Generally, the Bancroft rule applies: emulsifiers and emulsifying particles tend to promote dispersion of the phase in which they do not dissolve very well; for example, proteins dissolve better in water than in oil and so tend to form oil-in-water emulsions (that is they promote the dispersion of oil droplets throughout a continuous phase of water).

Instability

There are three types of emulsion instability: flocculation, creaming, and coalescence. Flocculation describes the process by which the dispersed phase comes out of suspension in flakes. Coalescence is another form of instability, which describes when small droplets combine to form progressively larger ones. Emulsions can also undergo creaming, the migration of one of the substances to the top (or the bottom, depending on the relative densities of the two phases) of the emulsion under the influence of buoyancy or centripetal force when a centrifuge is used.

Surface active substances (surfactants) can increase the kinetic stability of emulsions greatly so that, once formed, the emulsion does not change significantly over years of storage.

“Emulsion stability refers to the ability of an emulsion to resist change in its properties over time.” D.J. McClements.[2]

Technique monitoring physical stability

Multiple light scattering coupled with vertical scanning is the most widely used technique to monitor the dispersion state of a product, hence identifying and quantifying destabilisation phenomena[3][4][5][6]. It works on concentrated emulsions without dilution. When light is sent through the sample, it is backscattered by the droplets. The backscattering intensity is directly proportional to the size and volume fraction of the dispersed phase. Therefore, local changes in concentration (Creaming) and global changes in size (flocculation, coalescence) are detected and monitored.

Accelerating methods for shelf life prediction

The kinetic process of destabilisation can be rather long (up to several months or even years for some products) and it is often required for the formulator to use further accelerating methods in order to reach reasonable development time for new product design. Thermal methods are the most commonly used and consists in increasing temperature to accelerate destabilisation (below critical temperatures of phase inversion or chemical degradation). Temperature affects not only the viscosity, but also interfacial tension in the case of non-ionic surfactants or more generally interactions forces inside the system. Storing a dispersion at high temperatures enables to simulate real life conditions for a product (e.g. tube of sunscreen cream in a car in the summer), but also to accelerate destabilisation processes up to 200 times.

Mechanical acceleration including vibration, centrifugation and agitation are sometimes used. They subject the product to different forces that pushes the droplets against one another, hence helping in the film drainage. However, some emulsions would never coalesce in normal gravity, while they do under artificial gravity[7] . Moreover segregation of different populations of particles have been highlighted when using centrifugation and vibration[8].

Emulsifier

An emulsifier (also known as an emulgent) is a substance which stabilizes an emulsion by increasing its kinetic stability. One class of emulsifiers is known as surface active substances, or surfactants. Examples of food emulsifiers are egg yolk (where the main emulsifying agent is lecithin), honey, and mustard, where a variety of chemicals in the mucilage surrounding the seed hull act as emulsifiers; proteins and low-molecular weight emulsifiers are common as well. Soy lecithin is another emulsifier and thickener. In some cases, particles can stabilize emulsions as well through a mechanism called Pickering stabilization. Both mayonnaise and Hollandaise sauce are oil-in-water emulsions that are stabilized with egg yolk lecithin or other types of food additives such as Sodium stearoyl lactylate.

Detergents are another class of surfactant, and will physically interact with both oil and water, thus stabilizing the interface between oil or water droplets in suspension. This principle is exploited in soap to remove grease for the purpose of cleaning. A wide variety of emulsifiers are used in pharmacy to prepare emulsions such as creams and lotions. Common examples include emulsifying wax, cetearyl alcohol, polysorbate 20, and ceteareth 20.[9] Sometimes the inner phase itself can act as an emulsifier, and the result is nanoemulsion - the inner state disperses into nano-size droplets within the outer phase. A well-known example of this phenomenon, the ouzo effect, happens when water is poured in a strong alcoholic anise-based beverage, such as ouzo, pastis, arak or raki. The anisolic compounds, which are soluble in ethanol, now form nano-sized droplets and emulgate within the water. The colour of such diluted drink is opaque and milky.

In food

Oil-in-water emulsions are common in food. Notable examples include:

- Vinaigrette – vegetable oil in vinegar; if prepared with only oil and vinegar (without an emulsifier), yields an unstable emulsion

- Mayonnaise – vegetable oil in lemon juice or vinegar, with egg yolk lecithin as emulsifier

- Hollandaise sauce – similar to mayonnaise

- Crema in espresso – coffee oil in water (brewed coffee), unstable

In medicine

In pharmaceutics, hairstyling, personal hygiene and cosmetics, emulsions are frequently used. These are usually oil and water emulsions, but which is dispersed and which is continuous depends on the pharmaceutical formulation. These emulsions may be called creams, ointments, liniments (balms), pastes, films or liquids, depending mostly on their oil and water proportions and their route of administration.[10][11] The first 5 are topical dosage forms, and may be used on the surface of the skin, transdermally, ophthalmically, rectally or vaginally. A very liquidy emulsion may also be used orally, or it may be injected using various routes (typically intravenously or intramuscularly).[10] Popular medicated emulsions include calamine lotion, cod liver oil, Polysporin, cortisol cream, Canesten and Fleet.

Microemulsions are used to deliver vaccines and kill microbes.[12] Typically, the emulsions used in these techniques are nanoemulsions of soybean oil, with particles that are 400-600 nm in diameter.[13] The process is not chemical, as with other types of antimicrobial treatments, but mechanical. The smaller the droplet, the greater the surface tension and thus the greater the force to merge with other lipids. The oil is emulsified using a high shear mixer with detergents to stabilize the emulsion, so when they encounter the lipids in the membrane or envelope of bacteria or viruses, they force the lipids to merge with themselves. On a mass scale, this effectively disintegrates the membrane and kills the pathogen. This soybean oil emulsion does not harm normal human cells nor the cells of most other higher organisms. The exceptions are sperm cells and blood cells, which are vulnerable to nanoemulsions due to their membrane structures. For this reason, these nanoemulsions are not currently used intravenously. The most effective application of this type of nanoemulsion is for the disinfection of surfaces. Some types of nanoemulsions have been shown to effectively destroy HIV-1 and various tuberculosis pathogens, for example, on non-porous surfaces.

In fire fighting

Emulsifying agents are effective at extinguishing fires on small thin layer spills of flammable liquids (Class B fires). Extinguishment is achieved by encapsulating the fuel in a fuel-water emulsion thereby trapping the flammable vapors in the water phase. This emulsion is achieved by applying an aqueous surfactant solution to the fuel through a high pressure nozzle.

Emulsifiers are not effective at extinguishing large Class B fuel in depth fires. This is because the amount of agent needed for extinguishment is a function of the volume of the fuel whereas agents such as aqueous film forming foam (AFFF) need only cover the surface of the fuel to achieve vapor mitigation.

Uses

Emulsions are mainly used in many major chemical industries. In the pharmaceutical industry, they are used to make medicines that are more tasty, to improve value by controlling the amount of active ingredients. The most popular emulsions are Non-ionic because they have low toxicity. Cationic emulsions are also used in some products because their antimicrobial properties. Antimicrobial is a substance that kills or avoids the growth of microorganisms such as fungi and bacteria. Emulsions are also used in making many hair and skin products such as various types of oils and waxes.

See also

- Emulsion dispersion

- Microemulsion

- Miniemulsion

- Pickering Emulsions

References

- ↑ Emulsion - Definitions from Dictionary.com

- ↑ “Food emulsions, principles, practices and techniques” CRC Press 2005.2- M.P.C. Silvestre, E.A. Decker, McClements Food hydrocolloids 13 (1999) 419-424

- ↑ I. Roland, G. Piel, L. Delattre, B. Evrard International Journal of Pharmaceutics 263 (2003) 85-94

- ↑ C. Lemarchand, P. Couvreur, M. Besnard, D. Costantini, R. Gref, Pharmaceutical Research, 20-8 (2003) 1284-1292

- ↑ O. Mengual, G. Meunier, I. Cayre, K. Puech, P. Snabre, Colloids and Surfaces A: Physicochemical and Engineering Aspects 152 (1999) 111–123

- ↑ P. Bru, L. Brunel, H. Buron, I. Cayré, X. Ducarre, A. Fraux, O. Mengual, G. Meunier, A. de Sainte Marie and P. Snabre Particle sizing and characterisation Ed T. Provder and J. Texter (2004)

- ↑ J-L Salager, Pharmaceutical emulsions and suspensions Ed Françoise Nielloud,Gilberte Marti-Mestres (2000)

- ↑ P. Snabre, B. Pouligny Langmuir, 24 (2008) 13338-13347

- ↑ Anne-Marie Faiola (2008-05-21). "Using Emulsifying Wax". TeachSoap.com. TeachSoap.com. http://www.teachsoap.com/emulsifywax.html. Retrieved 2008-07-22.

- ↑ 10.0 10.1 Aulton, Michael E., ed (2007). Aulton's Pharmaceutics: The Design and Manufacture of Medicines (3rd ed.). Churchill Livingstone. pp. 92–97, 384, 390–405, 566–69, 573–74, 589–96, 609–10, 611,. ISBN 9780443101083.

- ↑ Troy, David A.; Remington, Joseph P.; Beringer, Paul (2006). Remington: The Science and Practice of Pharmacy (21st ed.). Philadelphia, Pennsylvania, USA: Lippincott Williams & Wilkins. pp. 325–336, 886–87. ISBN 0-7817-4673-6.

- ↑ "Adjuvant Vaccine Development". http://www.nano.med.umich.edu/Platforms/Adjuvant-Vaccine-Development.html. Retrieved 2008-07-23.

- ↑ "Nanoemulsion vaccines show increasing promise". Eurekalert! Public News List. University of Michigan Health System. 2008-02-26. http://www.eurekalert.org/pub_releases/2008-02/uomh-nvs022608.php. Retrieved 2008-07-22.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

-solution.jpg)